Solder pallets are key part of the manufacturing process. Since it’s a tool, the pallets has to be:

- well designed for the job

- precisely manufactured and assembled

- made from the right material

We continuously improving our design and manufacturing department to give solutions for our costumers raising manufacturing problems while lowering the cost of manufacturing.

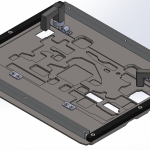

Pallet materials: high temperature resistant ESD plastic material specifically designed for soldering process and/or tool-aluminium. The aluminium soldering pallets are hard anodized and /or teflon coated. In critical areas we use titanium inserts, this allow us to go down as thin as 0,2mm wall thickness.

Design and quote: As start we request data of the products (gerber, odb++, most 2d or 3D formats fine to work with) and if possible a sample as well. If costumer request it or the product or the process more complex one of our sales engineer visits and discuss the work at the costumers site, basic guideline of the design and requirements are agreed on personal visit.

A quote is made within 24 hours after the visit. If the offer is accepted design work starts and within 24-72 hours a drawing sent by e-mail in 2D and 3D to the costumer.

Note: all data handled with maximum security, any informations given to our company stays between us and the costumer. If requested we provide dedicated FTP server space to our costumers which is only used by them and our engineer (each costumer got separate FTP address and space).

Manufacturing: After drawing approved we start the CAM programing and put the job into the manufacturing schedule, the production happens on very accurate CNC milling centers. The manufacturing time depends on the complexity of the product but we always give updates by e-mail about the status of the process. Delivery dates always follows costumer needs!

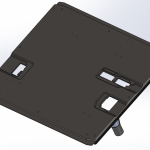

Top plates and hats: Pallets can be with or without top hat systems, depends on product and costumer requirements.

Pcb can be hold in position by simple clamps or spring loaded pushers (as on the picture above), if top hat is used the PCB can be fixed by the top hat as well, which can save cycle time.

Top hats are made from ESD material as well as the pallets. All components assembled on it are made from either ESD material, stainless steel (pushers, sleeves, springs) or tool aluminium. There are solutions where sensitive components needs to be fixed in position, for that purpose high temperature silicone rubber is used.

Other mechanisms:

- u-clamp systems (as picture above) when only a few components needs to be fixed and not cost effective to use top hats

- dedicated fixing, any type of “tool” can be made for the pallets to give extra positioning or fixing for components.

List of other solutions (these can be also accessed from the drop down menu on the top part of the site):

Last edited by admin on February 12, 2013 at 11:44